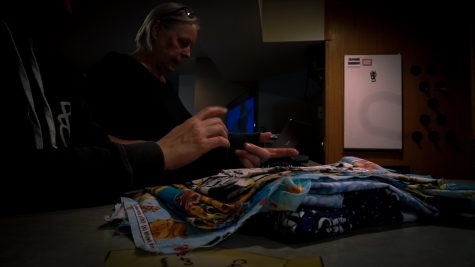

Fitted: How a Mother-Daughter Team Are Stepping Up to help the Medical Supply Shortage

Peg and Kathryn Steffen make masks during the COVID-19 crisis, which has created a nationwide shortage

After the CDC’s encouragement of fabric masks and the current online homemade mask trend, curious retiree Peg Steffen was prompted to make her own in her West Liberty home. Kathryn, her daughter, and a medical professional at the University Hospital recognized the need for more masks during what was arguably the beginning of the coronavirus pandemic.

“[I told Kathryn] you need to tell me what kind of mask you want,” Peg Steffen said, “So then we started making surgeon caps to go under the face shields.”

Together they found a pattern that Kathryn medically approved of: the Olson mask. The pattern specifies the dimensions of three fabric pieces that are easily sewn together to create a close-fitting article. The masks are designed to be washed and reused. As of now, the mother-daughter team has made over twenty masks for both adults and children to preserve the dwindling supply of highly effective masks at the hospital.

“We have a hierarchy of our [mask] needs,” Kathryn Steffen said, “We have our N95s. Those are completely reserved for our COVID patients and patients that we suspect have COVID.”

Steffen explained that while fabric masks are not as tight as N95s (masks that can filter out particulate infectious material) or as tight as surgical masks, homemade masks have been shown to decrease the transmission of droplets. Droplets, of course, could contain infectious material.

“That is to decrease asymptomatic transmission,” Kathryn Steffen said, “So there’s a lot of people that may not show signs of coronavirus but may be infected and able to transmit that infection.”

Kathryn reports that following the CDC’s recommendation of fabric masks in public spaces to reduce asymptomatic transmission, the hospital has allowed staff to wear homemade fabric masks in addition to a plastic face shield.

“Now our nurses are wanting more and more of these [masks] so they have them in the hospital when they’re interacting with family, and out and about,” Kathryn Steffen said.

Their fabric masks, Steffen says, is part of a larger demand for medical supplies. Fortunately for those seeking extra protection from the novel coronavirus, homemade masks are evidently simple to make. Peg Steffen reports that it takes approximately 30 minutes to produce a single mask while the price of that only amounts to the cost of fabric, pipe cleaners and elastic. However, the Steffens detailed the nationwide shortage of elastic, reporting the difficulty of purchasing the stretchy material both in stores and online.

Despite this, the Steffen mother-daughter team show no signs of stopping their production by initiating a mask design change to preserve their reported two and a half yards left of elastic.

“And so,” Peg Steffen said, “we’re trying to do whatever we can to get these masks made for the University of Iowa Hospital and for friends and family.”

Your donation will support the student journalists of Iowa City High School. For 2023, we are trying to update our video and photo studio, purchase new cameras and attend journalism conferences.

01010011 01100101 01101110 01100100 00100000 01001000 01100101 01101100 01110000 00101110 00100000 01010100 01110010 01100001 01110000 01110000 01100101...